The Client

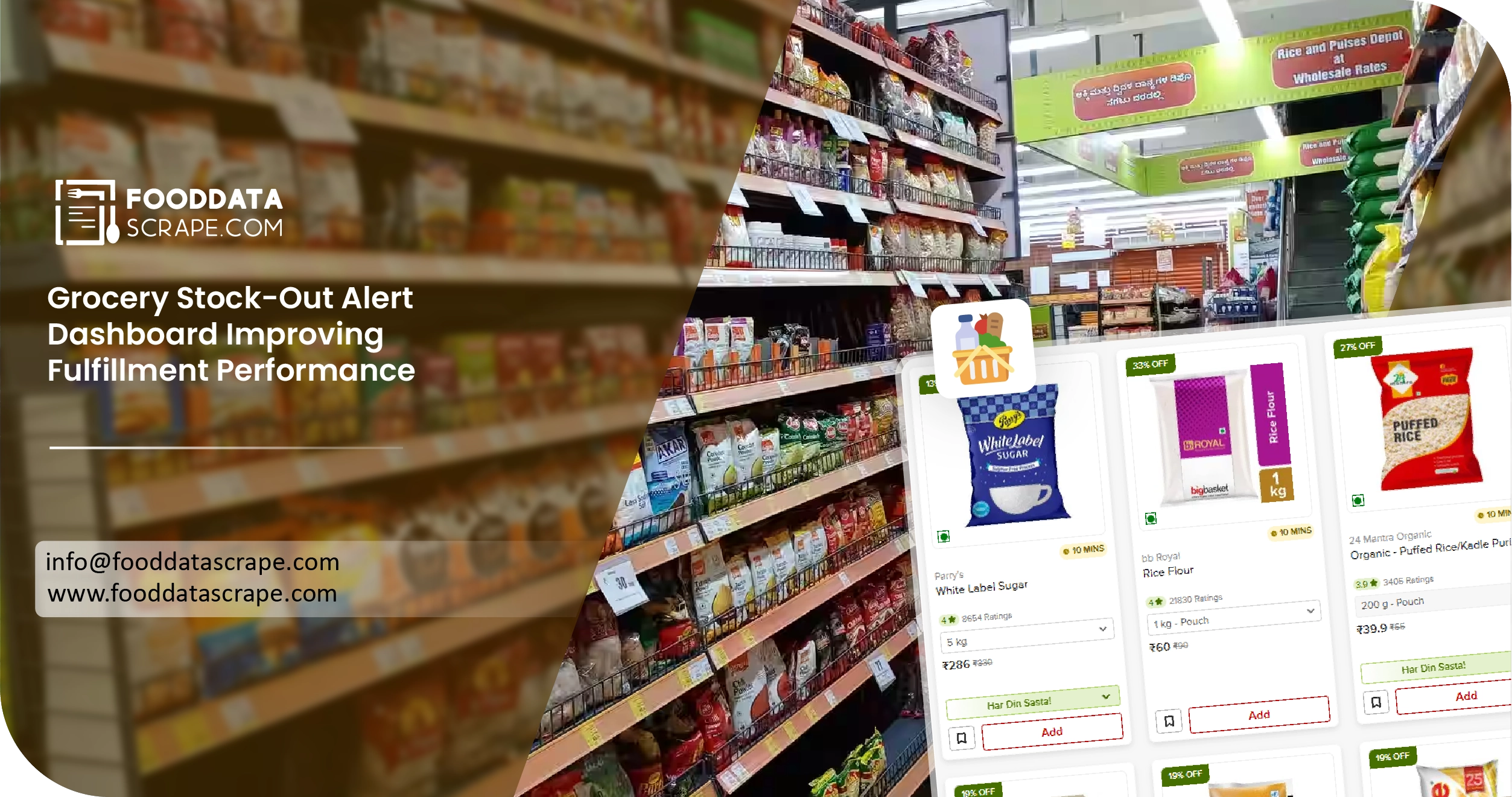

The client is a fast-growing retail grocery brand operating across multiple cities, managing thousands of SKUs across fresh, packaged, and household categories. As the business scaled rapidly, leadership identified the need for Retail Grocery Inventory Data Extraction to gain unified visibility into stock movement, supplier performance, and store-level demand variations. With increasing online orders and frequent promotions, the operations team needed timely insights to reduce lost sales. By leveraging systems designed to Extract Grocery Stock-Out Alert Data, the client was able to respond faster to low-inventory situations, prioritize critical SKUs, and improve coordination between warehouses and stores. The client also focuses heavily on digital channels, where accuracy directly impacts customer trust. Using Online Grocery Stock Availability Data Scraping, the brand continuously tracks real-time availability signals, improves demand forecasting, and ensures consistent product visibility, resulting in higher fulfillment rates and improved customer satisfaction across platforms.

Key Challenges

- Fragmented Stock Visibility Across Channels: The client struggled with inconsistent inventory data coming from multiple apps and marketplaces. Without Web Scraping Grocery Stock-Out Alert Data, teams lacked real-time visibility, leading to delayed replenishment decisions, inaccurate reporting, and frequent customer complaints about unavailable items.

- Delayed Response to Sudden Demand Spikes: High-demand periods and flash discounts caused unexpected stock depletion. Limited use of Grocery App Data Scraping services meant the client could not detect rapid availability changes early, resulting in missed sales opportunities, manual firefighting, and increased pressure on operations teams.

- Dependence on Manual and Lagging Data Feeds: Inventory planning relied heavily on delayed partner reports and spreadsheets. The absence of reliable Grocery Delivery Scraping API Services restricted automation, slowed alert generation, and made it difficult to scale monitoring across cities, stores, and third-party delivery platforms simultaneously.

Key Solutions

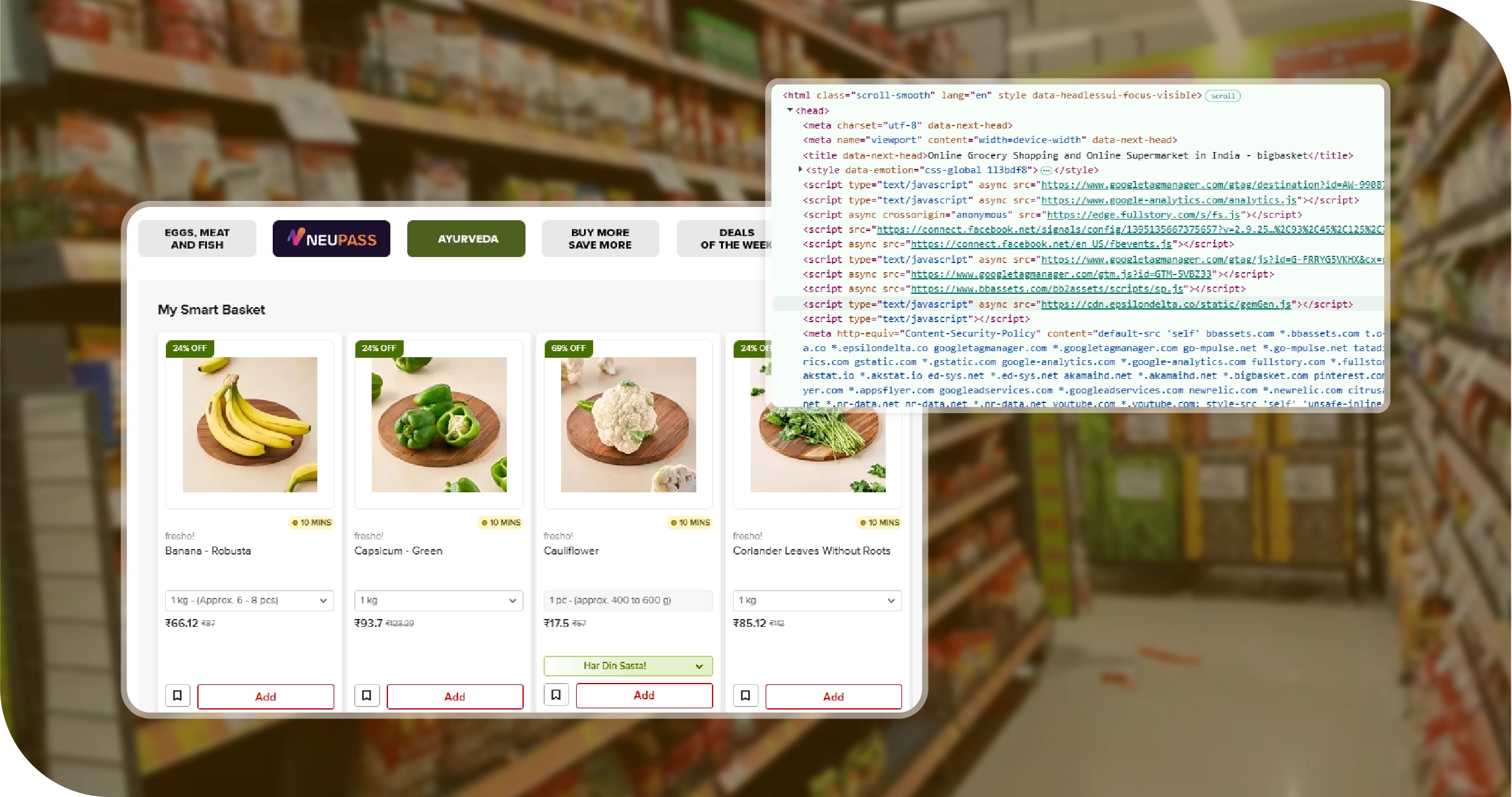

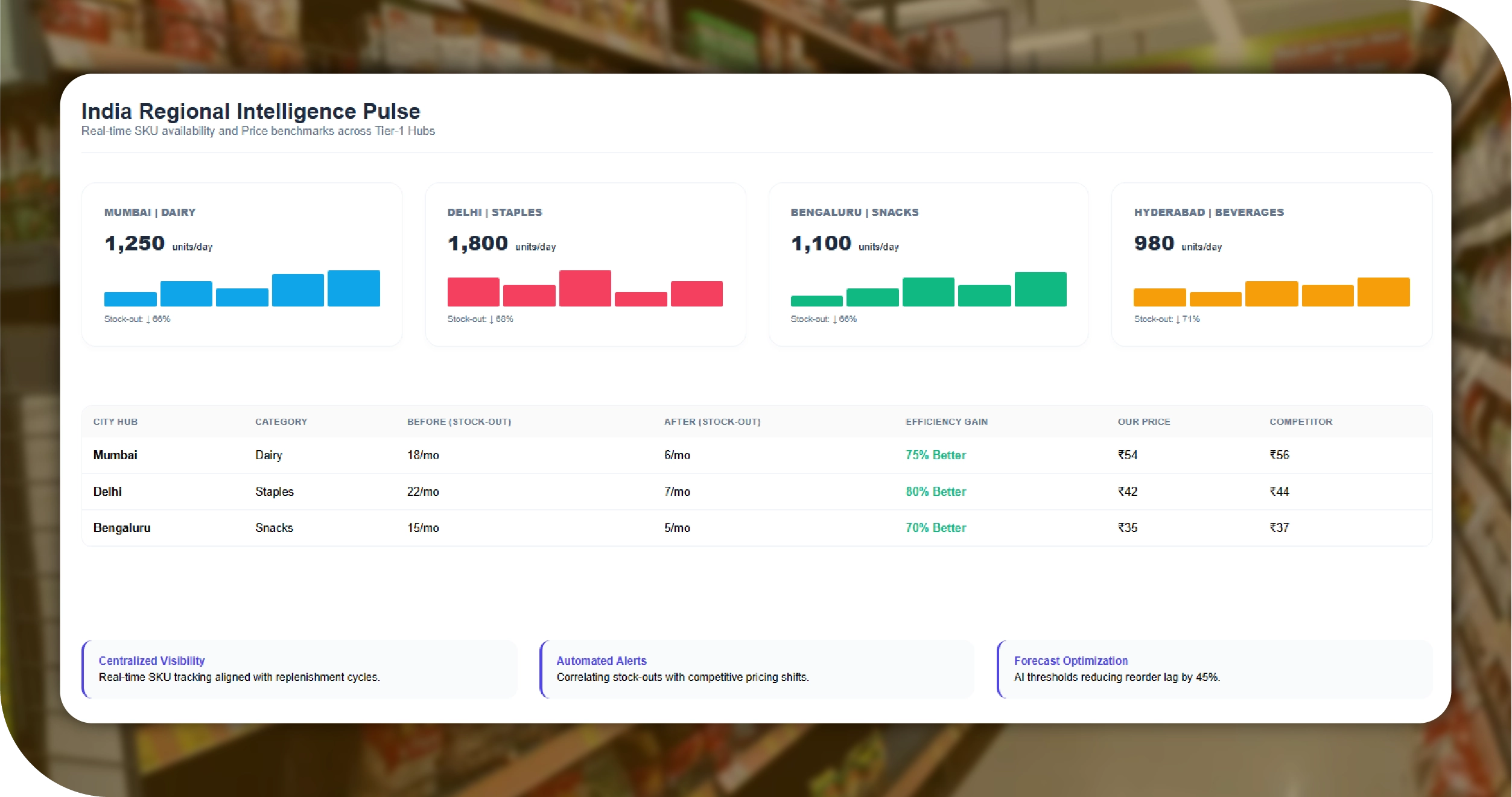

- Centralized Real-Time Inventory & Price Visibility: We deployed a unified monitoring system that consolidated stock and pricing signals across stores and apps. The Grocery Price Dashboard enabled operations teams to view SKU-level availability, detect anomalies instantly, and align replenishment actions with real-time market conditions.

- Automated Alerts with Competitive Price Context: Our solution introduced automated alerts combined with live competitor benchmarks. Using a Grocery Price Tracking Dashboard, the client could correlate stock-outs with pricing shifts, promotional spikes, and regional demand changes, helping teams respond proactively rather than reactively.

- Data-Driven Planning and Forecast Optimization: We delivered advanced analytics powered by Grocery Pricing Data Intelligence, allowing planners to analyze historical trends, predict high-risk SKUs, and optimize reorder thresholds. This reduced manual effort, improved forecasting accuracy, and strengthened coordination between procurement and store operations.

Sample Data Overview from the Implemented Solution

| City | SKU Category | Avg Daily Demand | Stock-Out Frequency (Before) | Stock-Out Frequency (After) | Avg Price (₹) | Competitor Avg Price (₹) | Alert Response Time |

|---|---|---|---|---|---|---|---|

| Mumbai | Dairy | 1,250 units | 18 times/month | 6 times/month | 54 | 56 | 15 minutes |

| Delhi | Staples | 1,800 units | 22 times/month | 7 times/month | 42 | 44 | 12 minutes |

| Bengaluru | Snacks | 1,100 units | 15 times/month | 5 times/month | 35 | 37 | 14 minutes |

| Hyderabad | Beverages | 980 units | 14 times/month | 4 times/month | 28 | 29 | 16 minutes |

| Chennai | Personal Care | 760 units | 11 times/month | 3 times/month | 110 | 115 | 18 minutes |

Methodologies Used

- Platform-Specific Data Mapping Approach: We analyzed each grocery platform independently to understand unique data structures, update cycles, and availability signals. This method ensured precise SKU alignment across channels and reduced mismatches caused by differing naming conventions and category hierarchies.

- Time-Interval Based Data Capture Strategy: Data was collected at carefully defined intervals based on product velocity and demand sensitivity. High-moving essentials were monitored more frequently, allowing early detection of availability changes without creating unnecessary system load.

- Rule-Based Prioritization Logic: Custom business rules were applied to classify products by criticality, margin impact, and demand volatility. This methodology helped teams focus first on high-risk SKUs that could cause maximum revenue loss if unavailable.

- Correlation Analysis Between Demand and Supply Signals: We studied the relationship between order volume trends and supply fluctuations. By correlating these signals, the client gained clearer insight into whether stock-outs were driven by demand spikes, supplier delays, or distribution inefficiencies.

- Iterative Optimization Through Pilot Rollouts: The solution was first deployed in select cities and categories to test performance. Feedback from pilot results was used to fine-tune data rules, alert thresholds, and workflows before scaling across the full store network.

Advantages of Collecting Data Using Food Data Scrape

- Faster Operational Decision-Making: Real-time visibility into inventory conditions allows teams to act immediately instead of relying on delayed reports. This speed reduces reaction time during demand spikes, prevents prolonged product unavailability, and supports more confident, timely operational decisions.

- Reduced Revenue Loss from Stock Gaps: Early detection of potential shortages helps prevent missed sales opportunities. By addressing issues before shelves go empty, businesses protect daily revenue, improve order fulfillment rates, and maintain consistent product availability during peak shopping periods.

- Improved Customer Experience and Trust: Consistent product availability minimizes order cancellations and substitutions. Customers experience fewer disappointments, leading to higher satisfaction, stronger brand loyalty, and increased likelihood of repeat purchases across both online and in-store channels.

- Better Coordination Across Teams: Shared visibility enables smoother collaboration between procurement, warehousing, and store operations. Clear insights reduce miscommunication, align priorities, and ensure that replenishment actions are coordinated efficiently across locations and regions.

- Scalable and Future-Ready Operations: As store networks and product catalogs grow, the system adapts without added complexity. Automated monitoring and analytics support expansion into new markets while maintaining control, consistency, and performance across an increasing operational footprint.

Client’s Testimonial

“Managing availability across multiple cities was one of our biggest operational challenges. This solution completely changed how we respond to inventory gaps. The real-time visibility and automated alerts helped our teams act faster and with more confidence. We saw a clear reduction in stock-out incidents, smoother coordination between stores and warehouses, and measurable improvement in customer satisfaction. What impressed us most was the accuracy of insights and how easily the system scaled with our growth. It has become an essential part of our daily operations and long-term planning strategy.”

Operations Director

Final Outcomes:

The final outcome of the engagement delivered measurable and sustainable improvements across the client’s grocery operations. With real-time visibility and automated alerts, stock-out incidents were reduced significantly, leading to higher on-shelf availability and improved order fulfillment rates. Teams shifted from reactive issue handling to proactive planning, enabling faster replenishment and better supplier coordination. Data-driven insights supported more accurate demand forecasting, reduced manual intervention, and optimized inventory thresholds across locations. Customer satisfaction improved as cancellations and substitutions declined, directly impacting repeat purchases and brand trust. The availability of structured Grocery Store Datasets also empowered leadership with reliable performance metrics, supporting smarter strategic decisions, scalable expansion, and long-term operational efficiency across both online and offline channels.